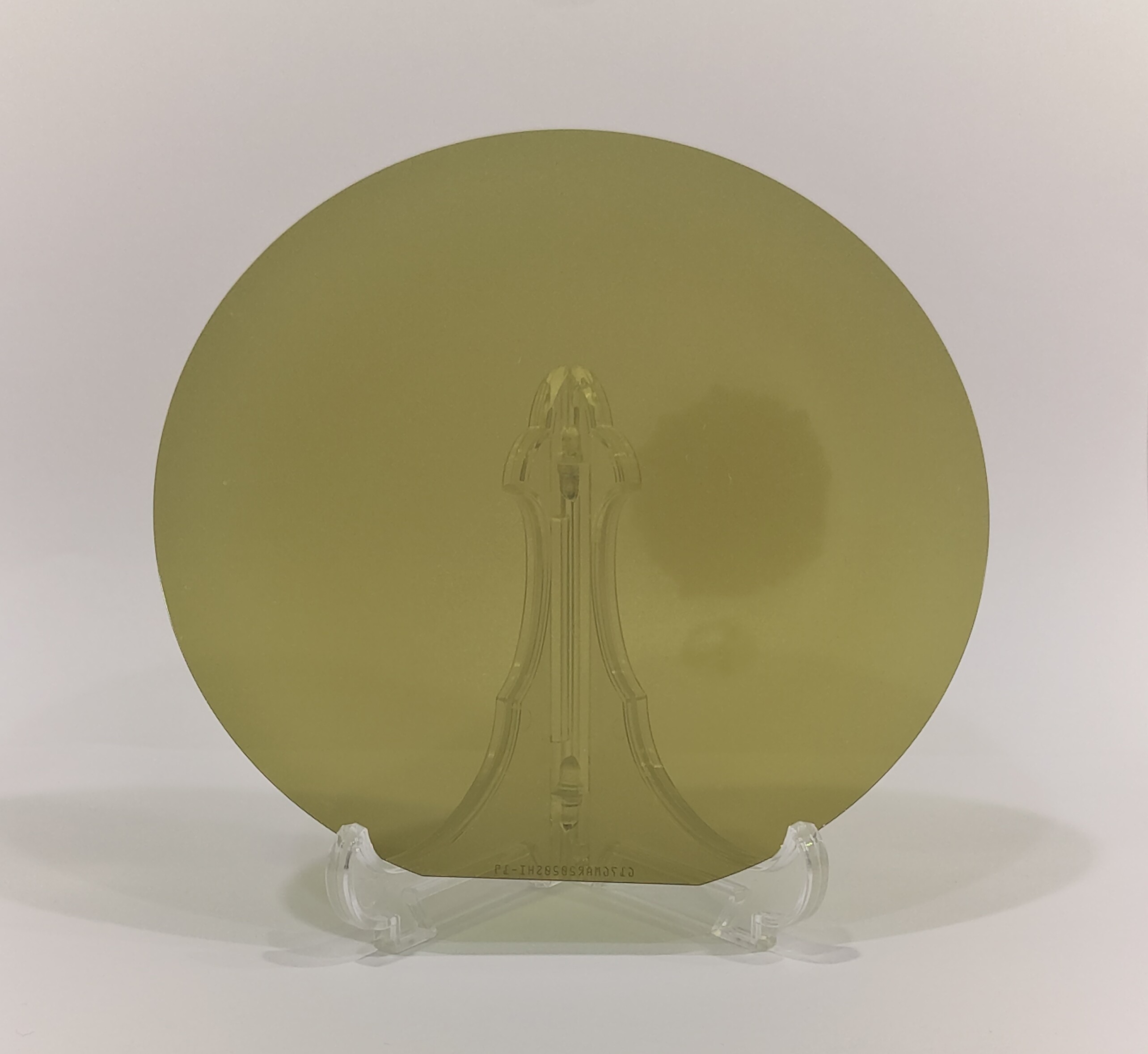

Silicon Carbide (SiC) enables engineers to achieve high-voltage power demands for charging stations in a cost-effective way.

SiC power electronics provides higher energy efficiency over existing Si electronics while reducing the form factor by around 10x.

Invertors made of SiC can operate at higher temperatures and voltages compared to those of made of Si, and reduce energy loss during grid-compatible DC-AC conversion.